Working hours:

Mon-Sat:9.30am to 7.00pm

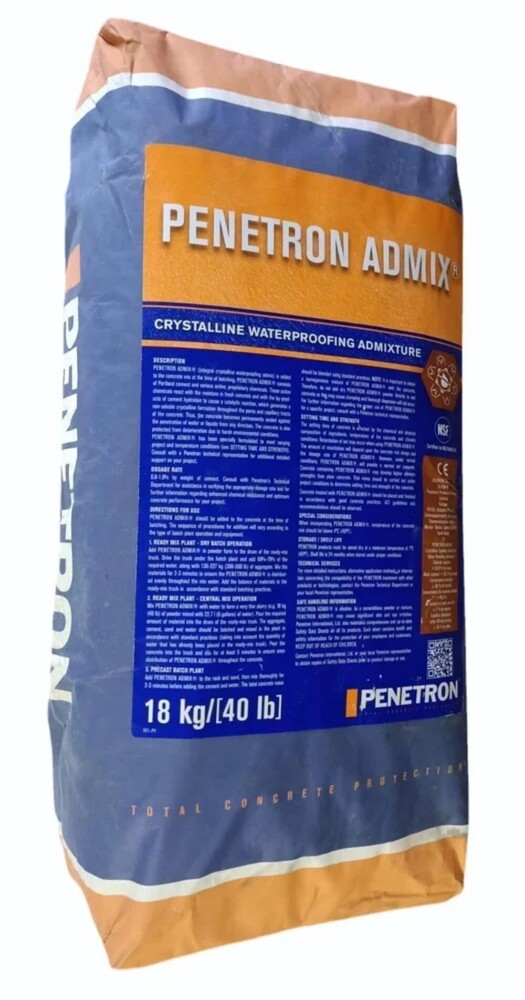

Penetron Admix Crystalline Waterproofing Admixture

Product Details:

- Water Absorption REQUIRED BASED

- Packaging Size REQUIRED BASED

- Flash Point REQUIRED BASED

- Purity REQUIRED BASED

- Usage & Applications REQUIRED BASED

- Chemical Form REQUIRED BASED

- Grade Standard REQUIRED BASED

- Click to View more

Penetron Admix Crystalline Waterproofing Admixture Price And Quantity

- 1000 Unit

- 300 INR/Kilograms

Penetron Admix Crystalline Waterproofing Admixture Product Specifications

- REQUIRED BASED

- Other

- REQUIRED BASED

- REQUIRED BASED Meter (m)

- REQUIRED BASED

- REQUIRED BASED

- REQUIRED BASED

- REQUIRED BASED

- REQUIRED BASED Meter (m)

- REQUIRED BASED

- REQUIRED BASED Meter

- REQUIRED BASED

- REQUIRED BASED

- REQUIRED BASED Gram per litre (g/L)

Penetron Admix Crystalline Waterproofing Admixture Trade Information

- NEW DELHI

- Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T)

- 1000 Unit Per Day

- 7 Days

- Yes

- Contact us for information regarding our sample policy

- As per requirement

- All India

Product Description

Penetron Admix Crystalline Waterproofing Admixture is a fast action formula that is commonly used in residential, commercial, and industrial buildings to make a protective coat over concrete surfaces for the prevention of chemical attacks, water, and rust. It is prepared by using top-quality chemical ingredients that are mixed within highly proportionate amounts which result in improved physical and chemical properties. Buy this product from us in bulk at a low price range.

DescriptionPenetron Admix (Integral Crystalline WaterproofingAnd Durability Admix) Is Added To The Concrete Mix At TheTime Of Batching. Penetron Admixs Various Active,Proprietary Chemicals React With The Moisture In FreshConcrete And With The Byproducts Of Cement HydrationTo Cause A Catalytic Reaction Generating A Non-solubleCrystalline Formation Throughout The Pores And CapillaryTracts Of The Concrete. Thus, The Concrete BecomesPermanently Sealed Against The Penetration Of Water OrLiquids From Any Direction. The Concrete Is Also ProtectedFrom Deterioration Due To Harsh Environmental Conditions.Penetron Admix Has Been Specially Formulated ToMeet Varying Project And Temperature Conditions (SeeSetting Time And Strength). Consult With A PenetronTechnical Representative For Additional Detailed SupportOn Your Project.AdvantagesResists Extreme Hydrostatic Pressure From EitherPositive Or Negative Surface Of The Concrete SlabBecomes An Integral Part Of The ConcreteHighly Resistant To Aggressive ChemicalsCan Seal Hairline Cracks Up To 1/51 (0.5 Mm)Allows Concrete To BreatheNon-toxic (Nsf 61 Certified For Potable Water Applications)Less Expensive Than Traditional MethodsPermanentAdded To The Concrete At The Time Of Batching AndTherefore Not Subject To Climatic RestraintsReduces Construction Scheduling TimeImproves Durability Of ConcretePermeability Reducing Admixture For HydrostaticConditions (Prah)Zero Voc Penetron Powdered Products Contain ZeroVolatile Organic Compounds And Are Safe For Use BothOutdoors And In Confined Indoor SpacesExceeds Requirements Of Astm C49s (SpecificPerformance Admixtures

Directions For UseDosage Rate:Powder: 0.8 1.0By Weight Of Cementing Materials. Consult With Penetron'sTechnical Department For Assistance In Verifying The Appropriate Dosage RateAnd For Further Information Regarding Enhanced Chemical Resistance AndOptimum Concrete Performance For Your Project.Liquid: Add 16 Ounces Of Penetron Admix Liquid For Every 100 Lb OfCementing Materials (1.0 L Of Penetron Admix Liquid For Every 100 Kg OfCementing Materials). Consult With Penetrons Technical Department ForFurther Information Regarding Enhanced Chemical Resistance And OptimumConcrete Performance For Your Project.Mixing:Powder: Penetron Admix Powder Must Be Added To The Concrete At TheTime Of Batching.The Sequence Of Procedures For Addition Will Vary According To The Type Of Batch Plant Operation And Equipment. The Following Are Some Typical MixingGuidelines. For More Detailed Information On Dosing Procedures, ContactYour Penetron Representative.Ready Mix Plant Dry Batch Operation: Add Penetron Admix In PowderForm To The Drum Of The Ready mix Truck. Drive The Truck Under The Batch PlantAnd Add 60 70 Of The Required Water, Along With 300-500 Lb (136 227 Kg) OfAggregate. Mix The Materials For 2-3 Minutes To Ensure The PenetronAdmix Is Distributed Evenly Throughout The Mix Water. Add The Balance OfMaterials To The Ready-mix Truck In Accordance With Standard BatchingPractices.Ready Mix Plant - Central Mix Operation: Mix Penetron Admix With WaterTo Form A Very Thin Slurry (E.g. 40 Lb (18 Kg) Of Powder Mixed With 6 Gallons(22.7 L) Of Water). Pour The Required Amount Of Material Into The Drum Of TheReadymix Truck. The Aggregate, Cement, Sand And Water Should Be BatchedAnd Mixed In The Plant In Accordance With Standard Practices (Taking IntoAccount The Quantity Of Water That Has Already Been Placed In The Ready mixTruck). Pour The Concrete Into The Truck And Mix For At Least 5 Minutes ToEnsure Even Distribution Of Penetron Admix Throughout The Concrete.Precast Batch Plant: Add Penetron Admix In Powder Form, To The Rock AndSand, Then Mix Thoroughly For 2 3 Minutes Before Adding The Cement

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+